Services

NorthStar Fluid Solutions provide fluid and fluid waste

management services for your project. During the project bidding

process, we work with our customers to determine the amount and

type of product required, based on geology, rig capability and

environmental regulations.

A fluids program is generated to streamline drilling fluid

performance once the project starts.

Fluid Programs

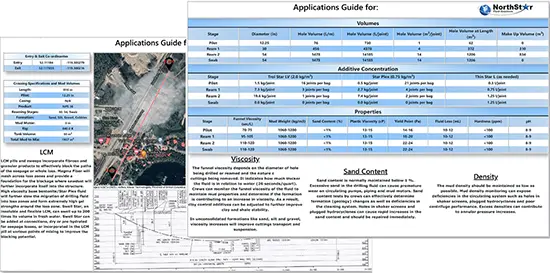

NorthStar Fluid Solutions provides customized drilling fluid programs for various types of projects, including Big Rig HDD, Light Rig HDD, Tunneling, and Foundation Drilling. Our EDFPs play a vital role in the planning and bidding process, accurately estimating fluid volumes, geological conditions, and product amounts required, allowing owners and clients to prepare and reduce costs. Our guide helps crews with mix ratios, recommended advancement rates, and solutions for unexpected problems, minimizing errors and downtime.

Products

NorthStar Fluid Solutions makes products that are easy to use and offer good value to customers. They believe in keeping things simple and won't recommend complicated product combinations. Their technical services team works to make sure their products are efficient and effective for drilling, boring, and coring projects.

Core Products

About Us

We have the experience to support your projects globally, with warehouses in the USA, Canada, and Mexico, and competitive pricing worldwide. Our field staff are knowledgeable in drilling fluid technologies and provide on-site support. Fluidos MayanStar was created to serve Mexico with local personnel, products, engineering, warehousing, and transportation. We prepare and plan customized mud programs to ensure project success, using only the necessary products for maximum performance. Our goal is to help you succeed with quality and value.

Worldwide Sourcing

NorthStar Fluid Solutions has the knowledge and expertise to develop strong supply relationships with top drilling fluid manufacturers. We stand behind our products, testing them in-house and in the field. With multiple stocking points in Canada, USA, and Mexico, and global relationships with manufacturers, we offer competitive pricing and availability worldwide.

Global Logistics

NorthStar Fluid Solutions offers unique and effective solutions for clients worldwide. We provide safe and cost-effective transportation options, with strong relationships with quality transportation companies and ocean carriers. Our services include rail car, flatbed, box van, LTL, and global container shipping, with document preparation.

QHSE

Safety, quality, and the environment are important to us. We work with manufacturers to provide the best products for our customers and regularly test samples to ensure they meet our standards. We provide health and safety information and toxicity testing to protect the environment. Our products have been tested for Aquatic Toxicity, Microtox, Metals, and salinity.